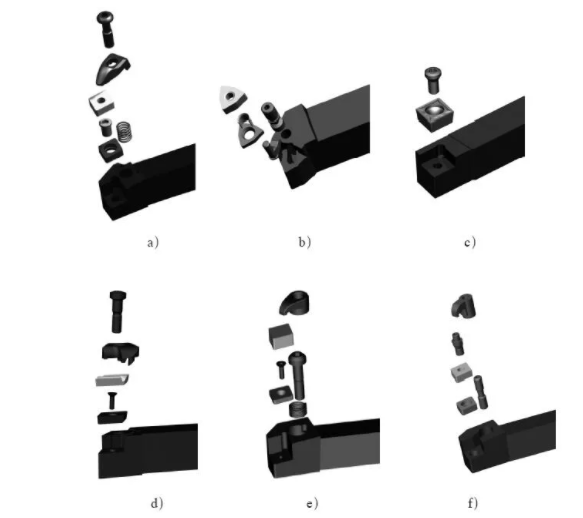

General turning tools holders are classified according to the type of clamping, in the form of Class D clamping, lever clamping, screw clamping, platen clamping and compound clamping. Class D clamping, as shown in Figure 3-11a, allows the use of double-sided inserts with a negative front angle. In turning, where stability and safety are key factors and reliable clamping of the insert will have a huge impact on the surface quality of the part, the Class D clamping system combines a downward clamping force with the positioning of the insert holder, which not only ensures rigid clamping of the insert, but also a high degree of repeatability during insert indexing. Lever clamping is shown in Figure 3-11b and uses single or double-sided inserts with ISO standard negative front angles. Lever clamping structure can obtain the most ideal three-way clamping force (down, to both sides of the blade), and also has the advantages of easy and quick blade removal, smooth chip removal, the disadvantage is that the rigidity is poor, the clamping stroke is short, the lever is damaged and screw spanner hole chip clearance is more difficult. Mainly used for medium and small machine tools cutting, is now the most commonly used structure of indexable turning tools in turning at home and abroad. Screw clamping, as shown in Figure 3-11c, has the advantage of being simple in structure and easy to operate compared to the D clamping system, enabling a more stable and smooth chip flow as well as the ability to use a variety of insert shapes. The disadvantage is poor impact resistance. The screw clamping system is the preferred choice for external and internal hole cutting on medium and small machines using positive front angle inserts. The advantage is that the clamping force is high and the structure is simple; the disadvantage is that it affects the chip flow and is mainly used for medium and heavy duty and interrupted cutting conditions. The advantages are reliable clamping and the ability to withstand large cutting loads and impact forces.

a) Class D pressing b) Lever pressing c) Screw pressing d) Platen pressing (alloy blades) e) Platen pressing (ceramic blades) f) Compound pressing

(i) External Turning

General external turning is the external surface of the part for processing, to obtain the required dimensional shape accuracy and surface quality. Ordinary cylindrical turning tools are divided into 95°, 90°, 75°, 60°, 45°, etc., 90°, 95° main angle tools cutting axial force is larger, radial force is smaller, suitable for turning slender shaft parts, 75°, 60°, 45° main angle tools are suitable for turning the outer circle of short and thick parts, of which 45° main angle tools can also be 45° chamfering turning. Negative angle insert turning tool economy is better than the positive angle insert turning tool, and the positive angle insert turning tool edge sharp, cutting fast, but the positive angle insert size is generally small, only suitable for small back draft, small feed processing, while the negative angle insert size can be manufactured larger, can be used for large back draft, large feed processing, tip strength is also better than the positive angle insert (the same shape, size, tip rounding of the insert). Different shapes of inserts have different edge strengths, different effective cutting edge lengths and different number of available tips.

(ii) Face turning

Face turning refers to the main cutting edge of the workpiece end face cutting process.

1.Note when turning end face

(1) The tip of the turning tool should be aligned with the centre of the workpiece to avoid leaving a tab in the centre of the turned end face.

(2) When the back draft is large, it is easy to tie the tool. Selection of back draft a: a=0.5mm~3mm for rough turning, ap=0.05~0.2mm for fine turning.

(3) The diameter of the end face is changing from outside to the centre, and the cutting speed is also changing, so the cutting speed must be calculated according to the maximum diameter of the end face when calculating the cutting speed.

(4) When turning a larger diameter end face, if there is a concave centre or convex belly, the turning tool and square tool holder should be checked, as well as whether the large slide plate is locked. In order to make the turning tool feed accurately laterally, the middle slide plate should be fastened to the bed and the back eating amount should be adjusted with the small tool holder.

(5) When the quality of the end face is high, the last cut should be made from the centre outwards.

2. Quality analysis of turning end face

(1) The end face is not flat, producing convex and concave phenomenon or leaving "small head" in the centre of the end face; the reason is that the turning tool is not installed correctly, the tool tip is not aligned with the centre of the workpiece, the back-eating amount is too large, and the lathe has a gap caused by the movement of the slide.

(2) Poor surface roughness. The reason is that the turning tool is not sharp, the manual tool walking shaking is not uniform or too fast, and the automatic feed amount is not properly selected.

(3) Inside hole turning

Inside hole turning characteristics: in a semi-closed state, it is not easy to observe the chip removal situation, affecting the quality of processing. Deep hole cutting often causes vibration of the tool bar, making the cutting edge wear fast, small diameter hole cutting using carbide tool bar, medium diameter above the use of vibration damping tool bar. When external turning is carried out, the length of the workpiece and the selected shank size have no influence on the tool overhang and can therefore withstand the cutting forces generated during machining. When boring and turning internal bores, the bore diameter and length of the part are extremely restrictive in tool selection as the depth of the bore determines the overhang.

Contact: Jacky Wang

Phone: +86 14714816052

Tel: +86 14714816052

Email: jacky@cncnctools.com

Add: Floor 1, Shixi Industrial area, Canton, Guangdong, China. 510288